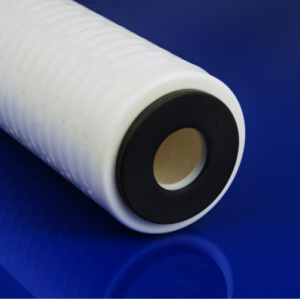

MS® PVDF Cartridge Filter

PVDF Cartridge are madecof polyvinylidene Fluorride, PVDF are characterized by High protein binding, low extractable levels, wide chemical compatibility, and high chemical inertness. They are certified bio safe, non pyrogenic & fully valideted to pharmaceutical standard. PVDF and polypropylene the unique two materials used in cartridge manufacturing are chemically inert not shedding and biologically safe according to FDA, USP and EEC requirements for pharmaceutical and food contact use. PVDF Cartridge Membrane is used in filtering the highly corrosive Solutions such as strong acids, bases solution and solvents. The membrane has about 80-95% porosity & uniform pore size distribution. Moreover, the filtration area of each cartridge is as high as 0.7 m² Therefore it it offers High flow rate, Low pressure drop & Long service life. These can be steam sterilize direct or reverse as per standard operating data.

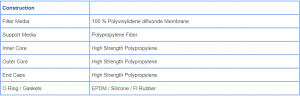

- Description

Description

Features

- The membrane stack consists of reinforced-type PVDF filter membrane and imported deflector layer, and possesses superior properties of heat-resistance and chemical-resistance.

- Hydrophobic membrane with small adsorption.

- Possessing better performance of oxidation resistance and heat-resistance and wide application Experiencing 100% integrity test before ex-factory

- Each Pharmaceutical Grade filter cartridge has been washed by injection water

- Each Electronic Grade filter cartridge has been washed by ultra pure water.

Technical Specifications

Sizes

5″, 10″, 20″, 30″, 40″ Long

Micron Rating

0.2 ∼ 5.0 Micron

Filtration Area

More Than 0.7 m² Per 10″ cartridge

Outer Diameter

28 mm

Maximum Differential Pressure(25°C)

Positive direction: 0.42 Mpa

Reverse direction: 0.21 Mpa

Applicable PH value

1.0 ∼ 14.0

Working Temperature & Differential Pressure

≤ 80°C(Differential Pressure: 0.2 Mpa)

Configuration

Double Open Type (DOE Type)

Code 7 F (226 O Ring Design)

Code 7 S (226 O Ring Design/Flat)

Code 3 F (222 O Ring Design)

Code 3 S (222 O Ring Design/Flat)

Applications

- Sterilized gas Filtration for food & beverage and wine

- High pure electronic chemical liquor

- Pharmaceutical

- Food, beverage and making wine

- Filtration of gas with high and low temperature and steam

- Petrochemical industry

- Sterilized transport of compresses air

- Oxidizing gas and liquid

- Fine filtration for solvent, liquor and printing ink etc.

- Much finer prefiltration