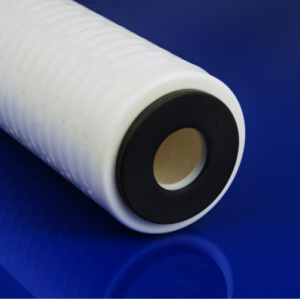

Pleated Filter

Introduction

MS®membrane pleated filters use patent “U” and “Matrix” pleated technology which can improve the features of cartridge s. Compare with the traditional pleating,”U” and “Matrix” can reaches up to 80-200% more effective filtration area with twice the flow rate. In that case, material performance is also filly played. MS membrane provide superior flow and greater contaminate capacity. It brings the cartridge excellent flow rate and long service life, and MS is one of the most professional manufactures of cartridge filters, specialized in filter elements and systems of F&B, Bioprocess, Microelectronics. MS have 5000 m² production area with 800 m² clean room class 10,000 and 200 m² clean room class 1,000. All of the filters test abide by ISO 9000 quality system standards. MS provide the solutions to assist the filter user in meeting the validation requirements of regulatory authorities with widely of industry.

Features

• Longer Service Time

• Absolute Retention Rate

• Low Protein Adsorption

• No Fiber Migration

• Widely Chemical Compatibility

• Patent Pleated Technology

Applications

• Pharmaceutical

• Medical and Biotech

• Food and Beverage

• Microelectronics

Quality

• FDA Listed Materials

• Validation Service

• ISO 9001 Certified Quality System

• Meets USP Class VI (121°C) Biological Safety Test for Plastics

• 100% Integrity Tested

• Clean room manufacturing environment

Showing 1–12 of 32 results