MS® Nylon Cartridge Filter

Nylon cartridge filter is precisely manufactured for use in critical filtrations within food, pharmaceuticals, biotech, dairy, beverages, blewing, semiconductor, water treatment & other demanding process industries. It’s upstream polyester support ensure resistance to pressure shocks. Nylon membrane is hydrophilic in nature. The membrane possesses broad chemical compatibilities & contains no surfactants. Nylon Cartridge filters are produced in controlled environments & under stringent production conditions that endure filter quality & cleanliness. Their assembly is performed integrally by thermal welding. This process minimizes the presence of oxidization of substance & yield a durable filter cartridge suitable for extended use. This can be sanitizes by chemical agents or by inline steaming. Nylon and polypropylene the unique two materials used in cartridge manufacturing are chemically inert not shedding and biologically safe according to F.D.A., USP and EEC requirements for pharmaceutical and food contact use. The filtration area of each cartridge is an high as 0.70 m². Therefore it offers high flow rate, Low pressure drop & long service life.

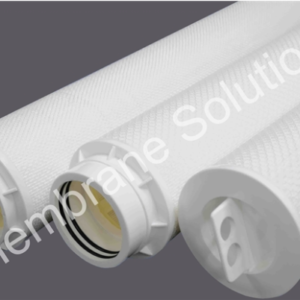

- Description

Description

Features

- The membrane stack consists of reinforced type nylon filter membrane and imported deflector layer

- The membrane is hydrophilic, has uniform pore size and good filter effect

- Possessing better performance high strength and alkali-resistance

- Experiencing 100% integrity test before ex-factory

- Each Pharmaceutical grade filter cartridge has been washed by injection water

- Each electronic grade filter cartridge has been washed by ultra pure water

Technical Specifications

Sizes

5″, 10″, 20″, 30″ 40″ Long

Micron Rating

0.2 ∼ 5.0 Micron

Filtration Area

More Than 0.7 m² Per 10″ cartridge

Outer Diameter

70 mm

Inner Diameter

28 mm

Maximum Differential Pressure(25°C)

Positive direction: 0.42 Mpa

Reverse direction: 0.21 Mpa

Applicable PH value

4 ∼ 13

Working Temperature & Differential Pressure

≤ 80°C (Differential Pressure: 0.2 Mpa)

Configuration

Double Open Type (DOE Type)

Code 7 F (226 O Ring Design)

Code 7 S (226 O Ring Design/Flat)

Code 3 F (222 O Ring Design)

Code 3 S (222 O Ring Design/Flat)

Applications

- Terminal filter for ultra pure water electronic industry

- Sterilization filtration for food, beverage and wine

- Drug liquid in medicine industry

- Much finer prefiltration