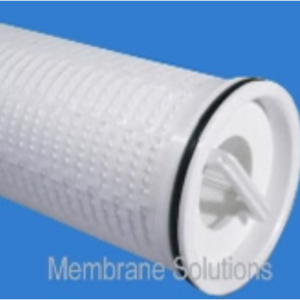

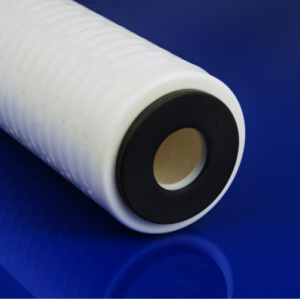

MS® CrossPure Cartridge Filter

Combining high flow rates and high solids is a challenge for most filters. MS® CrossPure Cartridge Filter meet this challenge with the highest flow and dirt holding combination available. Fewer filter change-outs means less costs associated with labor, disposal, and fluid losses. it can be used for a variety of hardware and for different flow rate request and fewer filter change-outs means less costs associated with labor, disposal, and fluid losses. The large diameter with bigger filtration area insures to reduce the number of filter cartridges and the dimension of housing required.

- Description

Description

Features

- Designed to fit inside existing 3M housing and provide an O-ring seal without housing modification

- High dirty holding capacity, longer service life

- less cartridge change out to save the cost

- O-ring design cause no bypass to ensure the filtration efficiency

- It is available in a variety of filter media to meet industry standards and chemical compatibility

Applications

- Industrial-Municipal Water,RO Prefiltration, Coolants

- Chemical-Quench water, Final Products

- Electronics-RO Prefiltration, Process Water

- Pharmaceutical-Process Water

Specifications

Materials of construction:

- Filter Medium: pleated Polypropylene, pleated Glass Fiber

- Support/Drainage: Polypropylene

- End caps: Glass fiber reinforced polypropylene

- O-ring Seal Material: EPDM, Fluorocarbon

Dimensions:

- Outside Diameter: 6.5″ (165 mm)

- Length: 40″ (1000 mm)

Recommended Operating Conditions:

- Maximum Temperature: Pleated Polypropylene: 82°C , Pleated Glass Fiber: 121°C

- Maximum Pressure: Pleated Polypropylene: 3.4 bar@82°C , Pleated Glass Fiber: 3.4 bar@121°C

- Recommended Change-out Differential Pressure: 2.4 bar@20°C

- Micron Rating: 1∼70μm

- Suggested Maximum flow rate: 1300 LPM