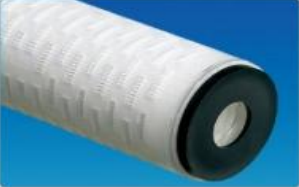

Features

- The membrane stack consists of MCE reinforced type micropore membrane and imported deflector layer.

- Better hydrophilicity; great water flux and better cut off effect

- Small adsorbability

- Possessing better performance of high-temperature resistance

- Experiencing 100% integrity test before ex-factory

- Each Pharmaceutical Grade filter cartridge has been washed by injection water

Applications

- Great infusion for medical purpose

- Variety of pure water and medicine liquid

- Terminal filter for mineral water

- Pure water after reverse osmosis

- Food & Beverage etc

- Filter for high pure water

- Much finer pre-filtration

Technical Specifications

Sizes

5″,10″,20″,30″,40″ Long

Micron Rating

0.1 ~ 5.0 Micron

Filtration Area

More Than 0.7 m² Per 10″ cartridge

Outer Diameter

70 mm

Inner Diameter

28 mm

Maximum Differential pressure(25°C)

Positive direction: 0.42 Mpa

Reverse direction: 0.21 Mpa

Applicable PH value

3 ~ 7.5

Working Temperature & Differential Pressure

≤80°C (Differential Pressure: 0.2 Mpa)

Configuration

Double Open Type (DOE Type)

Code 7 F (226 O Ring Design)

Code 7 S (226 O Ring Design/flat)

Code 3 F (222 O Ring Design)

Code 3 S (222 O Ring Design/flat)