F-1500 Insertion Turbine Flow Meter for Steam

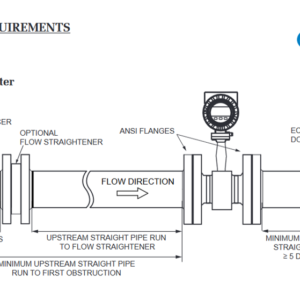

F-1500 Series Insertion Turbine Flow Meters are designed for accurate, cost-effective mass flow measurement of steam, high temperature liquids and gases. Insertion turbine flow meters are ideal for use in larger steam lines where downsizing the line size to improve flow measurement is not desirable. In these applications, the pitch of the turbine rotor is selected to match the expected steam flow velocity range in the pipe. This optimizes the operating range of the flow meter for the application.

The standard loop powered version of the meter is equipped with the internal temperature compensation required for direct mass flow measurement of saturated steam. Each F-1500 Flow Meter is provided with a 4-20mA analog output for flow rate, a pulse output for totalization and a built-in user interface and display. The standard loop powered meter also includes HART.

- Description